Vitrification

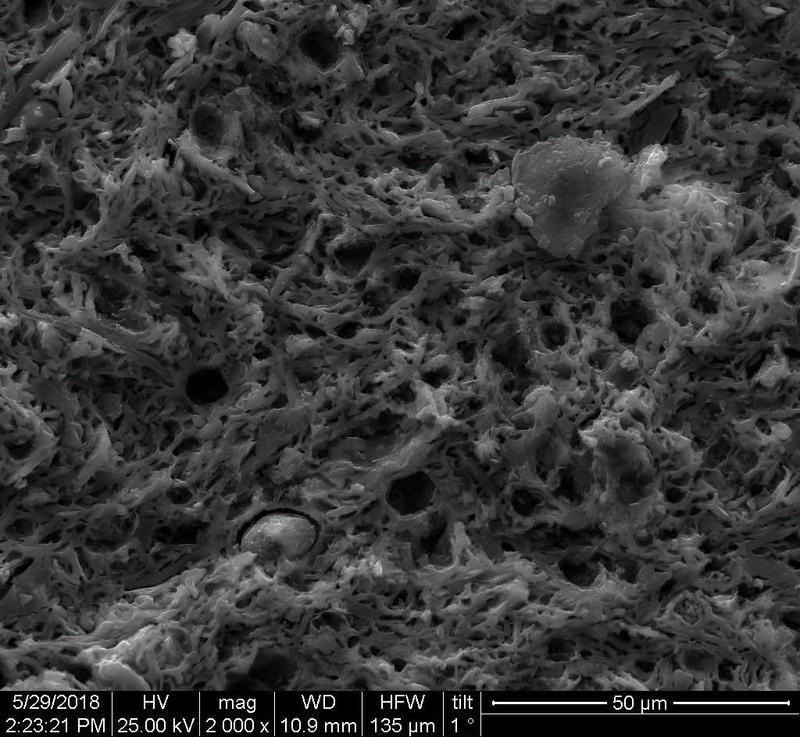

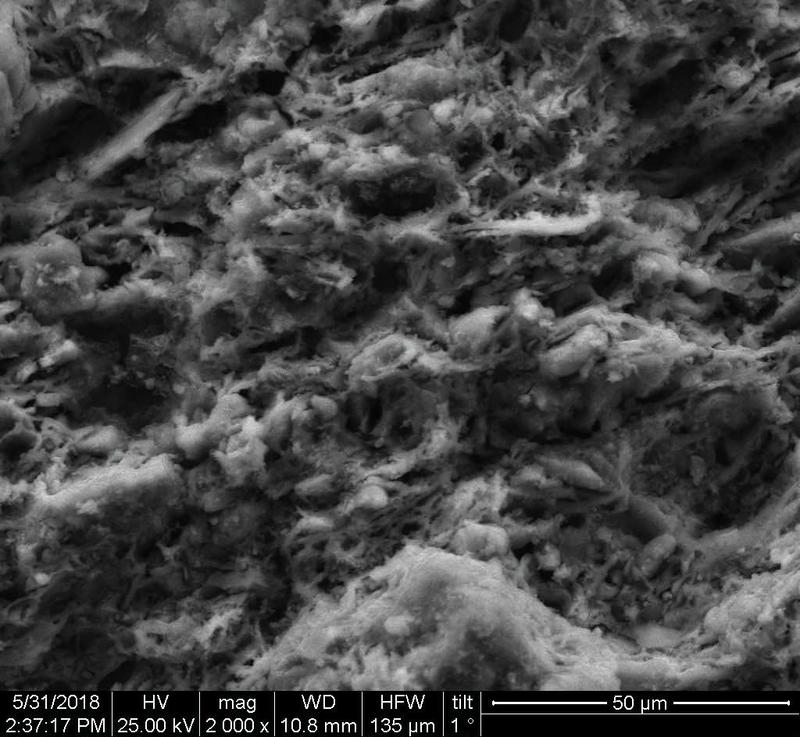

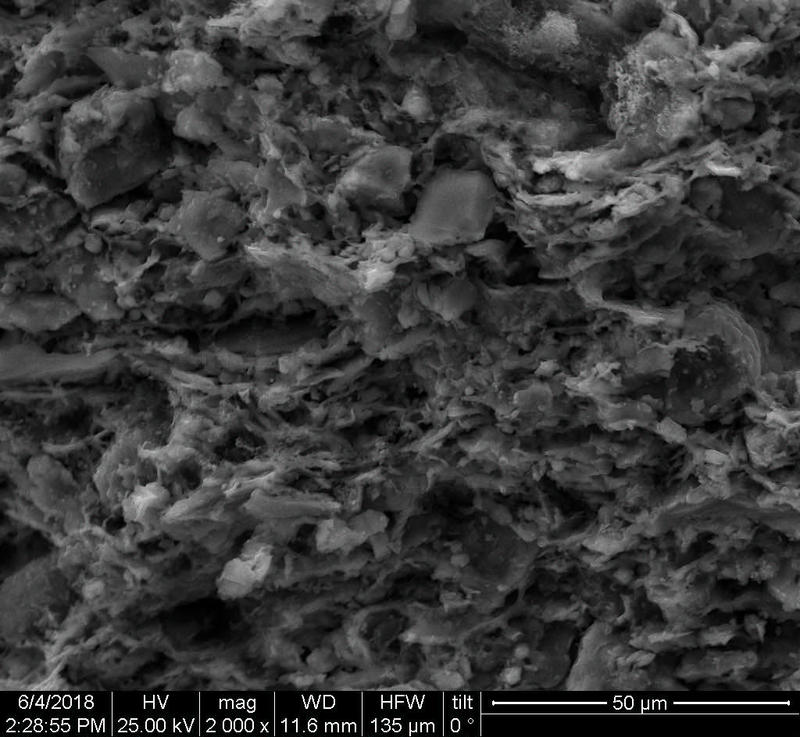

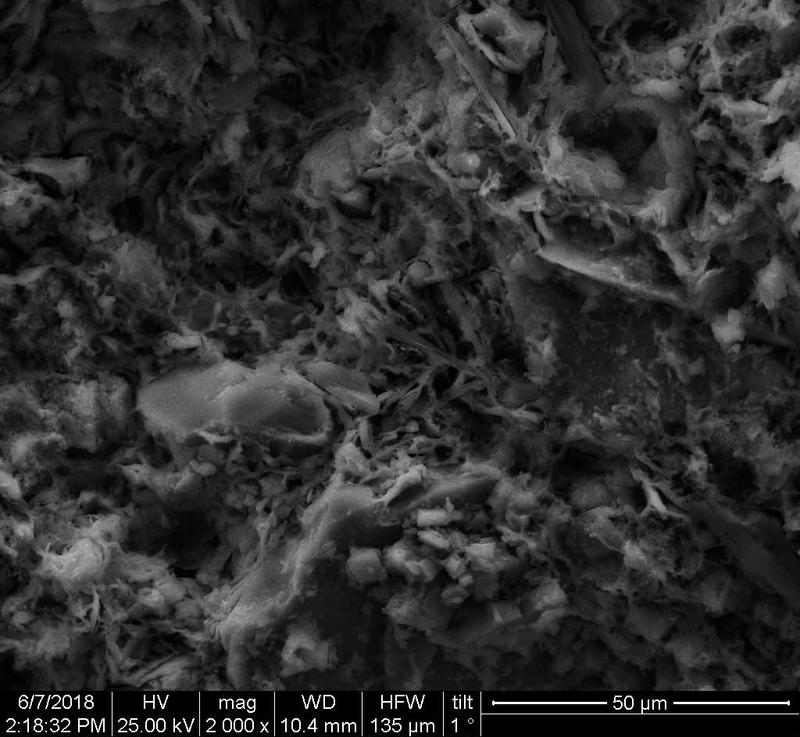

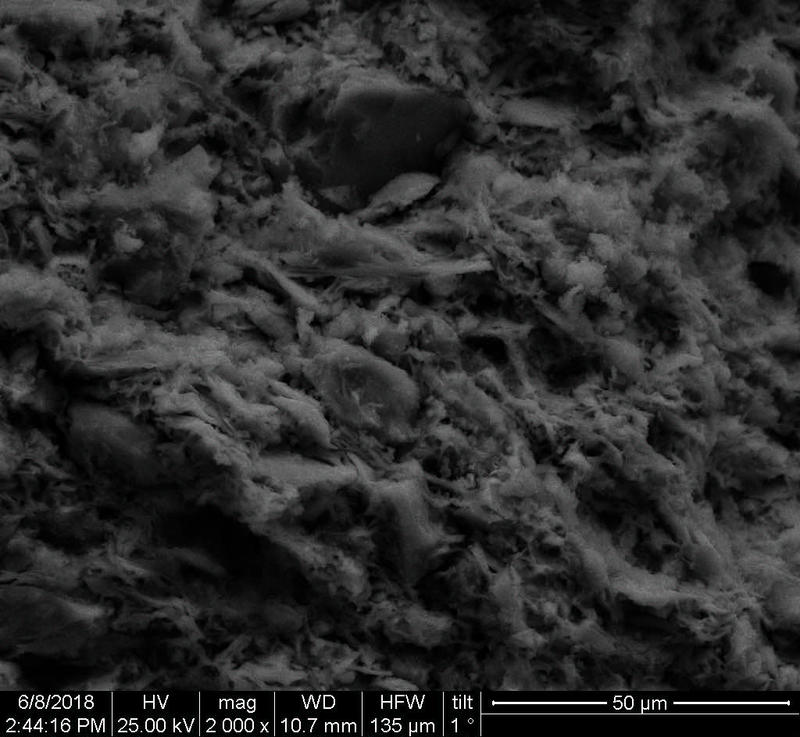

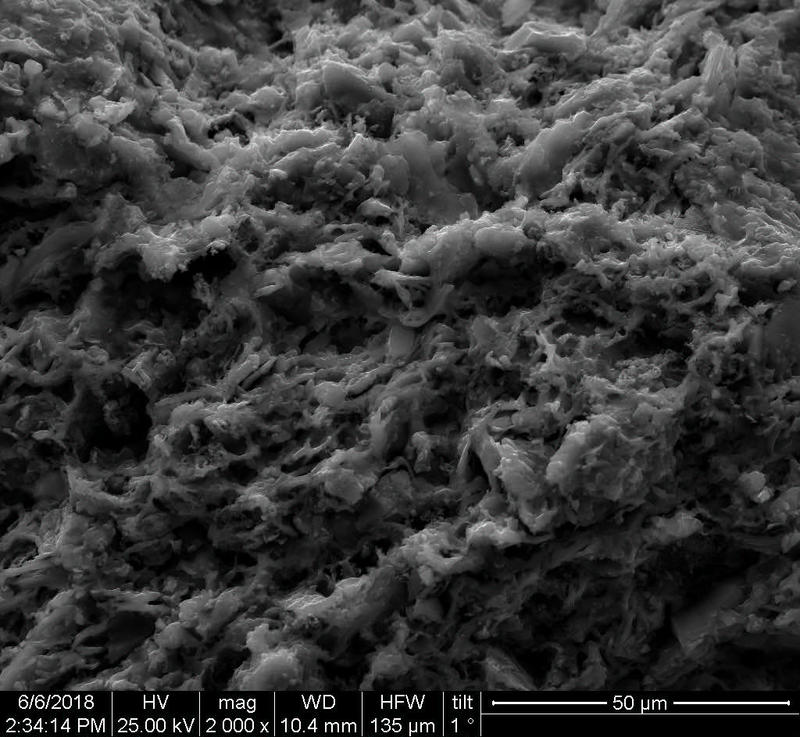

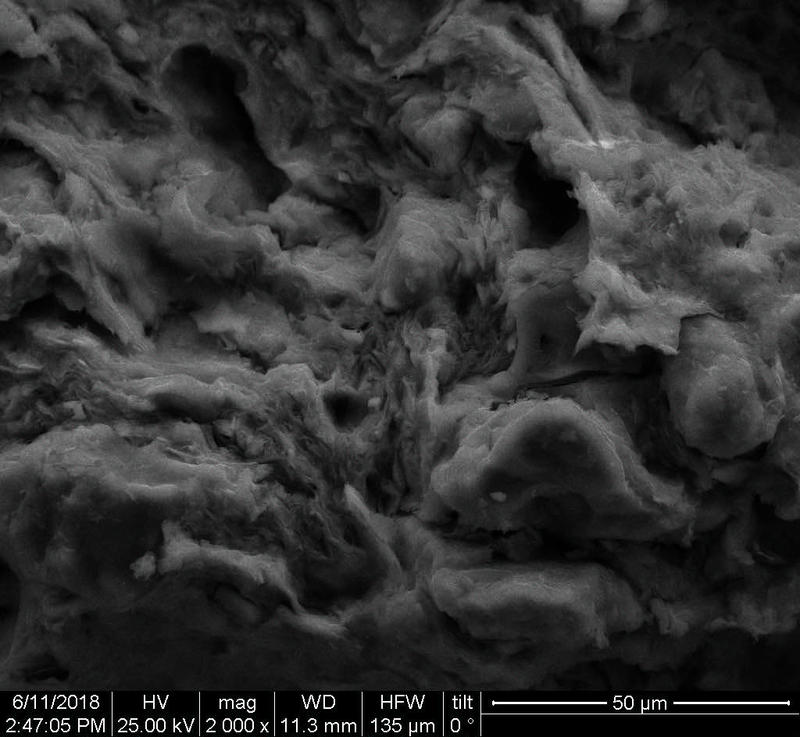

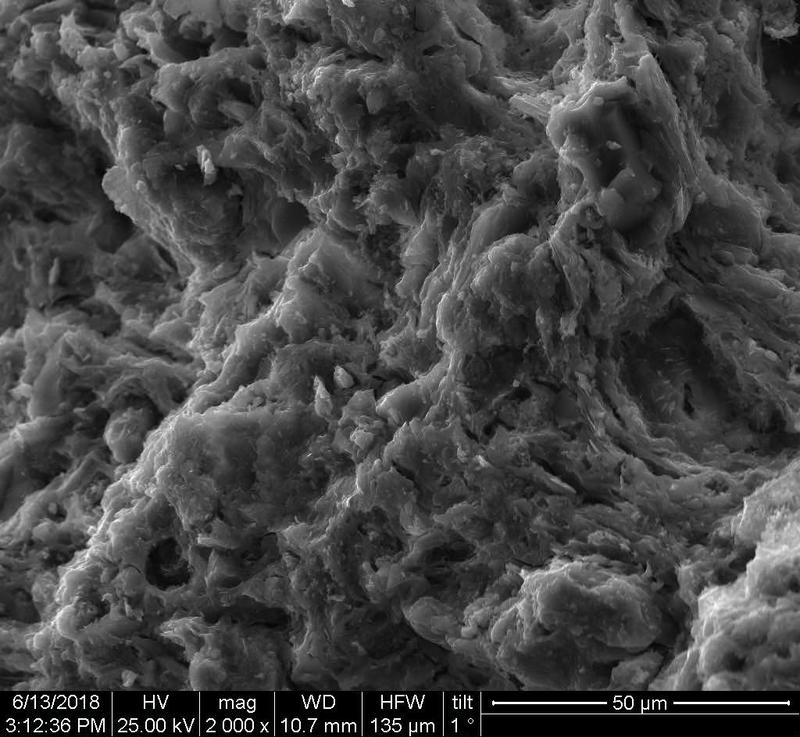

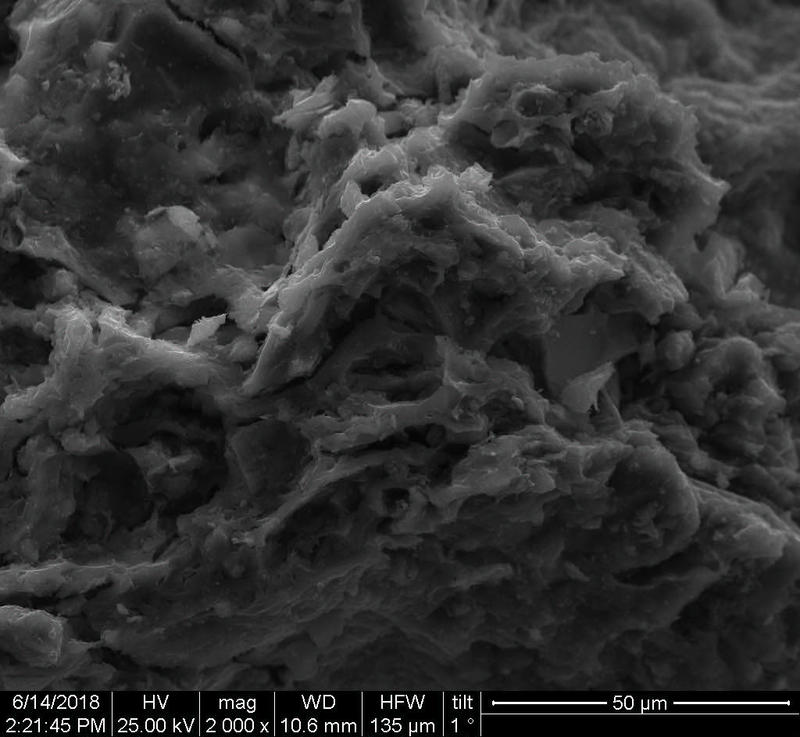

Vitrification is a process where clay particles melt into each other and physically change. This process makes pottery impervious to liquids. Watertight pottery provides food safety because bacteria would have less opportunity to penetrate into it and grow. Potters create a particular paste recipe to achieve this process and the calcium oxide content in this recipe plays an important role.

Calcium oxide, commonly known as lime, is a chemical compound with the formula CaO. CaO content within the pottery samples is important to consider when determining the vitrification and maximum firing temperatures reached during firing.

Clays that have more than 5% of CaO in their composition are called calcareous clays, and those with a lower amount of CaO are classified as non-calcareous. These types of clays react differently to the firing conditions. Therefore researchers need to know the CaO content within the samples to be able to determine the vitrification levels. Firing temperatures above 800°C can then be estimated according to the extent of the vitrification levels observed in the body.

Questions to think about,